Problem

Problem

- An existing main product (the box) was ugly and old-looking, with tubes and wires exposed and zip-tied in place.

- Their customers are lower leg amputees, who depend on this medical device to transform a more wobbly, unstable interface with something more firm and usable experience for the user.

- Marketing management wanted a neater, smarter look.

Action

Action

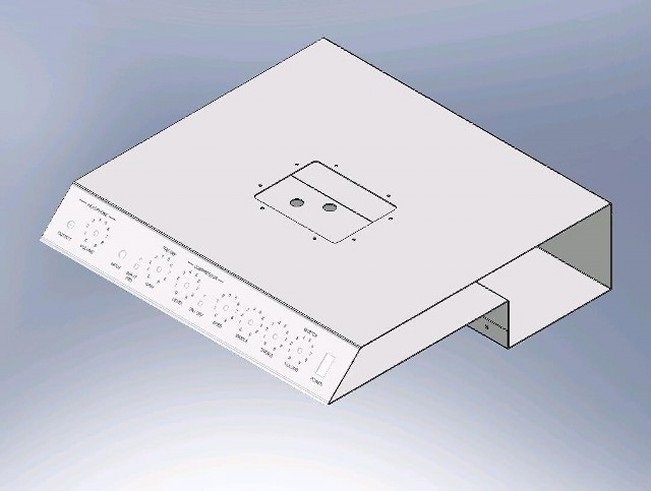

Designed a cosmetically pleasing cover that may be sold as an enhancement to the existing prosthetic device and used without making any changes to the product already in use and being sold.

Result

Result

Designed a cosmetically pleasing cover –

- Streamlined and attractive.

- Replaced the Zip Ties previously used to anchor the device.

- Provided an exceptional location for the control buttons.

- Neatly stored 1 ½ feet of control cable.

- Looked very good; a substantial improvement in appearance.

- Attach and snap on in place over the existing device.

- Prototyped the original concept for the Trade Show.

- Exceptionally strong design, so that even the SLS (Selective Laser Sintered) prototype endured actual user trials.

- The prototype could proceed directly to injection molding with no design changes.

Project Notes

Project Notes

Often, you cannot design everything over again in order to make a product more appealing, especially in the case of a medical device, which, if changed, would require some level of regulatory submission and approval. The best way to deal with a challenge like this is to be able to add something without requiring any change to the current FDA-approved product.