Product Design and Development

This includes everything from ideation to design drawings ready for production, from design start to design completion, including:

-

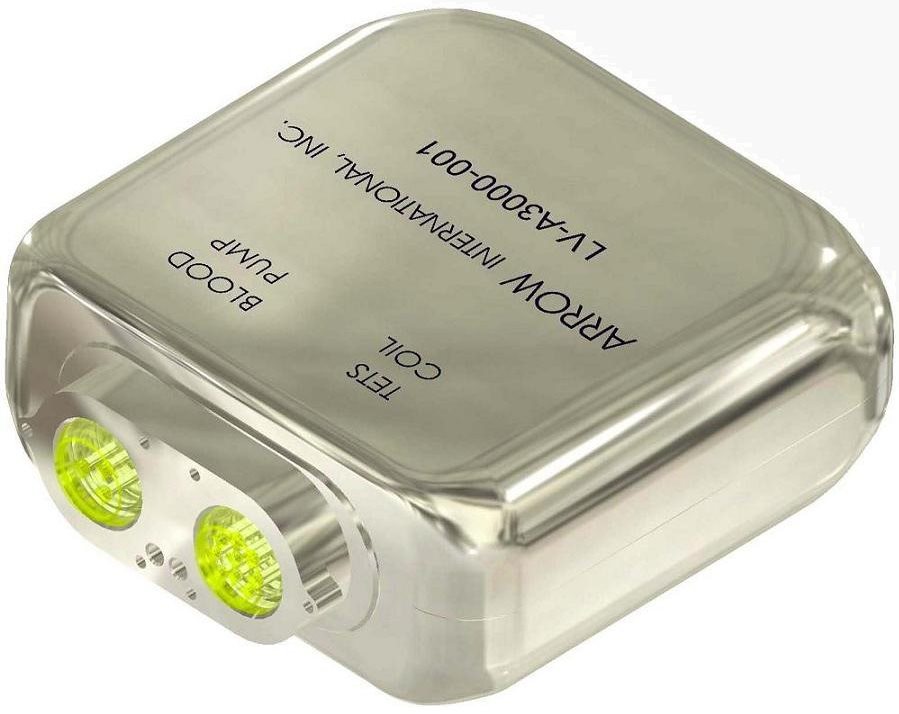

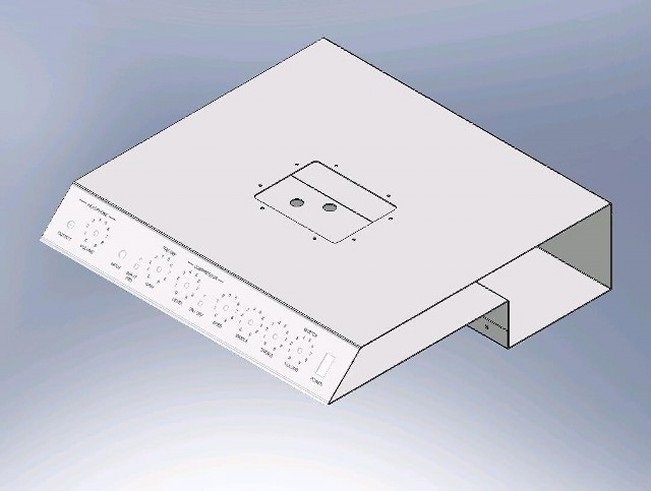

- 3D CAD models for injection molding, material removal and any other fabrication method.

- 2D drawings, with all detailing, specifications and assembly, ready for suppliers to use.

- Work with you through ALL design phases.

- Maintain all your revision controls and document your changes and revisions.

- Transparent online data for you: Revision records, cost, and Design progress, each available on browser or mobile device.

- Any of these options, or all of the above.

Design Rescue

Sometimes a design is persistently underperforming, or is resistant to improvement, or may have larger problems.

- Add a new feature to a product, or create a Next Generation Design.

- Complete a design that is not quite ready for prime time – or production.

- Sometimes the design itself can cause you problems: The choice of how to spec out something on a drawing, or a subtle 3D CAD model change can pile up scrap parts on your production line, cause your parts to fail in use, or make your product so hard to evaluate that each batch is tied up forever in Inspection.

Design for Manufacture & Scalability

Some products work great, but need design adjustments so that every part works as well as your prototype.

I know the changes to make so that:

-

- Each part manufactured works as well as the prototype.

- Production rate is rapid enough for you to meet customer demand.

- Production cost stays on target.

- Your medical device is MANUFACTURABLE.

- Your medical device transitions from prototype to SCALABLE.