Problem

Problem

Clients often need more than simply geometry creation. They need analysis.

Action

Action

With a background in Manufacturing Engineering, Process Engineering, Tooling Design, and Quality Control, and with all the standard data processing software, and SolidWorks.

Result

Result

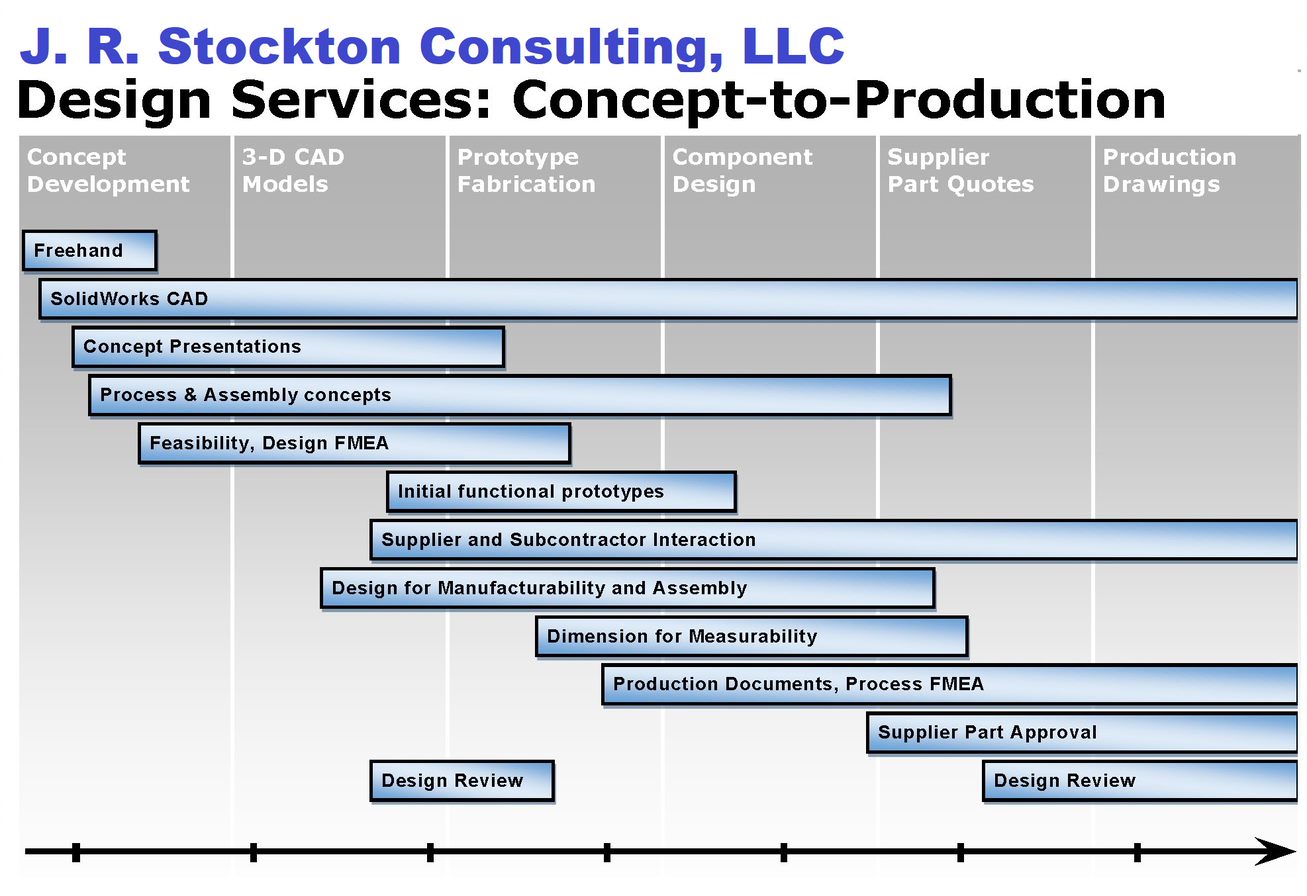

A wide range of design services from Concept-to-Production, including –

- Failure Mode & Effects Analysis (FMEA), both Design FMEA and Process FMEA

- Dimensional Stack-up Analysis

- Workgroup PDM and Drawing Configuration Management

- Finite Element Analysis, Single Parts

- Stress analysis quantifying the estimated results of proposed design changes.

- Design Inputs

- Design Outputs

- SolidWorks Premium Edition

- Finite Element Analysis, Non-dynamic (FEA)

- Mobile CAD Workstation

- Workgroup PDM (Product Data and Revision Management)

- MS Office, Word, Excel, PowerPoint, Outlook

- Zoom Meetings

- Effective SolidWorks solid modeling in,

- Solids

- Surfaces

- Assemblies

- Drawings, layouts, diagrams and illustrations

- Sheet metal

- FEA (Finite Element Analysis), single component

- Plastic and injection molded

- Composite

- Elastomeric and elastic variables

- Machined metal

- FMEA (Failure Mode and Effect Analysis, both Process and Design)

Project Notes

Project Notes

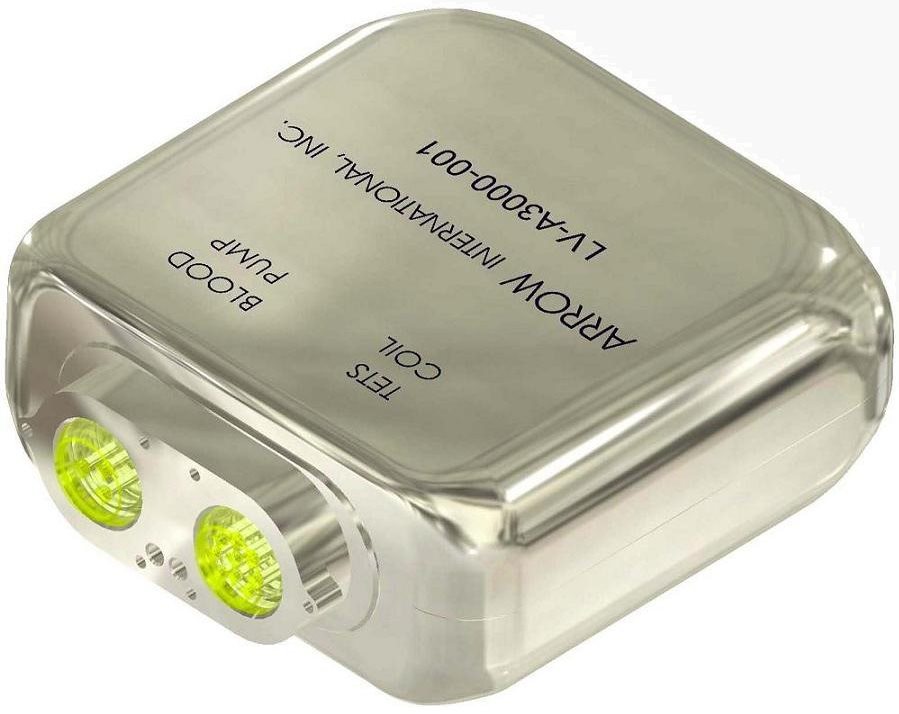

- One part of design is the generation of geometry, for both aesthetic appearance and mechanical fit.

- Analysis involves much more information about the part, and how it interacts with part geometry.