Problem

Problem

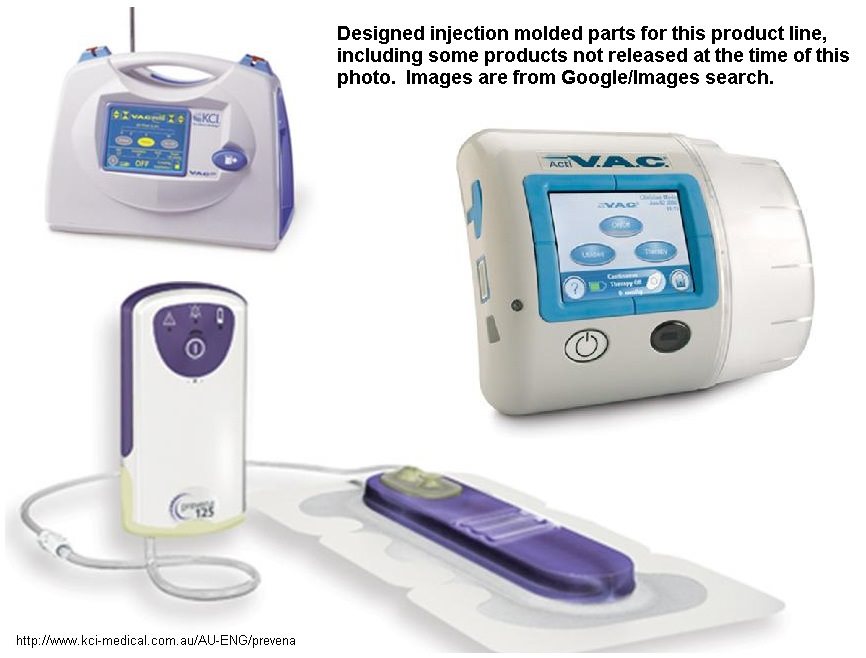

A vacuum-dependent device prototype presented with multiple seal leaks, such that the electrical engineer could not operate the device enough to perform the electrical system diagnostics on the system. The reservoir seals and several internal seals could not close enough to effectively hold the approx. 1/7th atmosphere.

Action

Action

- I began to diagnose the device, isolating it’s leaks and vacuum breaches.

- Added the design changes that would remedy the seal problems with respect to flexing of the injection molded parts and moving parts.

- Worked with the prototype vendors to create remedied parts to my new specifications.

- Received, reassembled, and checked the entire assembled device.

- With all of the seals and latches operating, and mechanically functioning in all respects, our Electrical Engineer was able to run all of his tests on the electrical controls and complete verification on the new vacuum device.

Result

Result

For the project, this meant that it could actually be tested, and that the manufactured medical device was more likely to function reliably in therapeutic use.

Project Notes

Project Notes

Other examples of Design Diagnostic and Design Rehab in this site are:

- Innovative Mechanical Design Solutions

- Torque Wrench Redesign (a total redesign)

- Prototype Development

- …as well as up to 1/3rd of my projects in any given year.